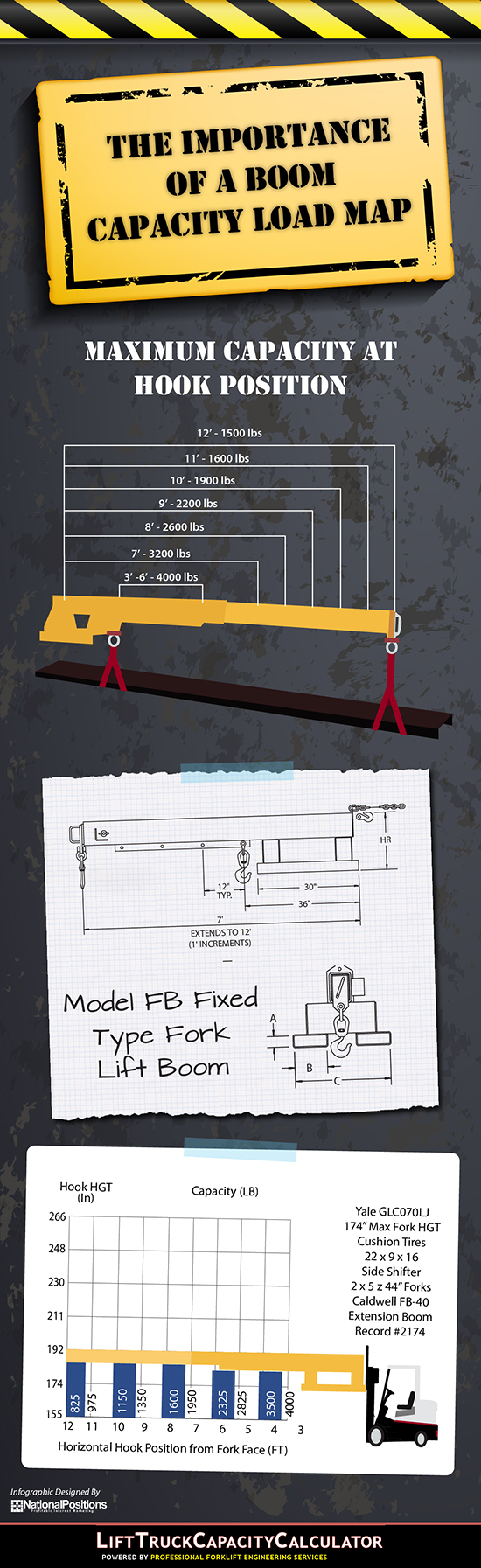

Understanding the capabilities and limitations of your machinery before use allows your employees to safely complete tasks. In addition, your business will see a decreased risk of injury, leading to greater productivity and efficiency. A boom capacity load map helps you achieve these goals, by giving your employees the information they need so they can safely lift materials in the warehouse or out on a job site.

Affixed to the forklift, the boom capacity load map shows the safe amount of weight that can be lifted at certain hook position intervals. The size of the load will affect the hook position, and you want to be sure to never lift over the capacity so that the highest levels of safety can be maintained at all times. Continually educating and retraining employees on the various equipment they use will ensure proper usage, and save time and money lost from injuries and broken machines.

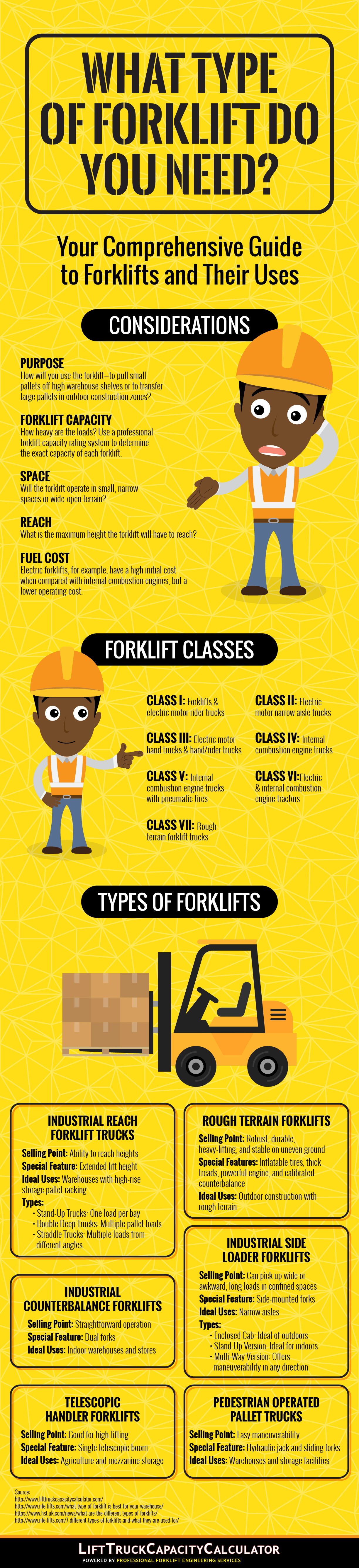

When you are in need of machinery to move products and other materials around your business or job site, using a forklift is one of the easiest and most efficient options. However, with the variety of forklifts available for the job, it can be difficult to decide which will be best for your situation. In order to solve this problem, it is important to consider a few factors.

Start by assessing the purpose of the forklift. Do you need it to pull pallets from a shelf or move large pallets around a construction site? What load capacity is needed to get the job done correctly and safely? Don’t forget to note the size of the space in which the forklift will operate. Choosing one too large will negate any benefits you hope to receive.

You also want to ensure that you have certified forklift operators who can easily operate the lift to help you cut down on time and expenses along the way. Research the type of forklifts available and assess your individual needs before buying or leasing for your company.

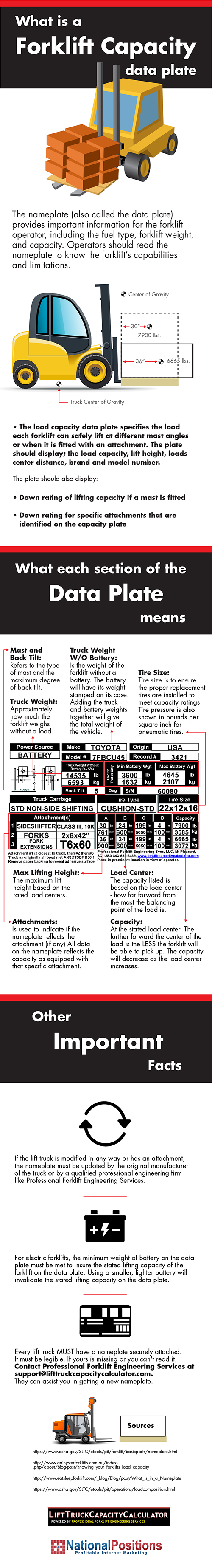

The data plate on a forklift is broken down into different sections, which each stand for a different characteristic and measurement. Some of these include:

Mast and Back Tilt Refers to the type of mast and the maximum degree of back tilt allowable.

Tire Size Ensures proper replacement tires are used to maintain levels of safety.

Load Center Gives a capacity based on how far forward from the mast the balancing point of the load is.

If any modifications are made to a forklift, or if it has an attachment, the forklift capacity plate must be updated to reflect the new capacity. Similarly, if a data plate goes missing or is illegible, you are required to replace it. To do so, contact Professional Forklift Engineering Services at support@lifttruckcapacitycalculator.com.

The maximum weight data placard on forklifts should never be regarded as the maximum amount able to be lifted. There are several factors that affect the lifting capacity, which is often reduced for various reasons. It is important to remember the lifting capacity is based upon the load center.

Did you know you lose weight-lifting capacity for every one inch beyond the actual load center? It is your responsibility to calculate the load center for any type of attachment used with the truck, including the original one. In addition, each time you switch attachments, it is essential to recalculate the load center and maximum load lift capacity of the forklift.

To learn more about the factors that affect the load center and load capacities, please feel free to continue reading the following infographic presented by Lift Truck Capacity Calculator. We can also provide assistance with determining the load center for a variety of attachments, as well as those that are worn by contacting us directly.

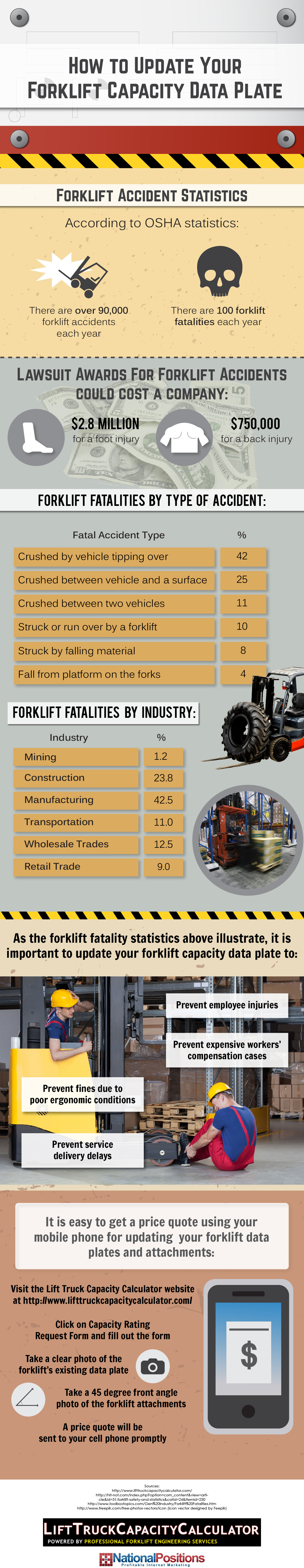

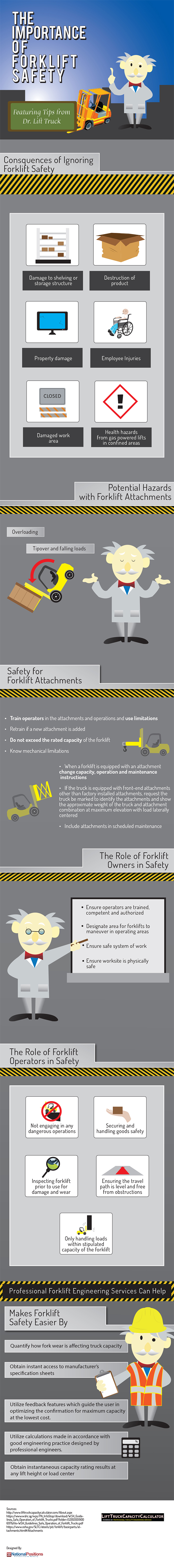

Forklift safety is not to be taken lightly. This equipment is involved in around 90,000 accidents every year and sometimes people sustain severely, and occasionally even fatal injuries from these incidents. Even if a forklift accident at the workplace doesn’t result in such serious consequences, it’s likely that a business will find still itself embroiled in workers’ compensation issues, and OSHA will always investigate the accident looking for regulatory violations. The infographic depicts the various recorded causes of accidents. Regardless of the ultimate resolution, a missing or incorrect data plate will be flagged, will result in OSHA fines, and can be legal fodder.

An incorrect or missing data plate can preclude an operator and the management team from understanding the lifting limitations of the machine. Properly trained forklift operators understand how to read the data plate and look for the forklift’s maximum capacity in a particular situation. Fortunately, there is now no reason to operate with an incorrect data plate because the specialists at Professional Forklift Engineering Services make it easy, quick, and cost effective to stay OSHA compliant. If we can help your business obtain the data plates and certifications you need please contact us for a quote.

When working in a warehouse, or for any business that owns and operates forklifts, taking proper safety precautions is of the utmost importance. Owners of forklifts need to ensure that operators are fully trained and authorized to work with the equipment in order to meet compliance standards. Additionally, work areas should be cleared of debris and clutter, to allow forklifts to move and operate freely. This helps reduce the number of injuries and keeps employers and employees aware of best practices for operation at all times.

If forklift safety plans are ignored, there are a number of potential consequences, including:

Damage to warehouse shelving or storage structure

Destruction of product

Property damage

Employee injuries

Damaged work area as a result of spills or broken shelving

Health hazards

In addition, overloading a forklift could cause it to tip over. Damaged products and equipment will end up costing your business more in repair and replacement costs, which can be avoided by taking the time to do the job the right way.

Forklift attachments should be inspected regularly so that repairs to broken forks and other equipment can be made immediately. Train all operators on your attachments and, when you add a new attachment, be sure to retrain all personnel. Know the mechanical limitations of each forklift, and change the capacity, operation, and maintenance instructions when a forklift is equipped with an attachment.

Forklift operators should remain safe when driving a forklift, and they should secure all products before transporting. Inspect the forklift before each use, and always ensure the travel path is free of obstructions before beginning a job.

Part of your job as a warehouse manager is to ensure that all of your equipment and machinery is in working order so that you can improve safety conditions for your employees and prevent accidents from happening. OSHA requires that daily pre-shift inspections of your powered industrial trucks, including forklifts, are completed to help achieve these goals. Before operating a forklift in your warehouse you want to perform a series of checks to make sure it is in working order.

With the engine off, check the condition and pressure of the tires. It is also important to inspect oil levels and see if the engine is leaking at all. The condition of the battery should also be noted so that it can be replaced if needed. Once your visual check is complete, ensure that all safety information and manuals can be easily accessed by the operator and that there is enough room above the forklift and in its path for it to be driven safely.

When you turn the engine on, the first thing you should do is listen for any unusual noises so that they can be immediately addressed. Check the brakes, steering, and gauges as well before driving the forklift. Other items that should get your attention include the forks, chain anchor pins, and hoses. If any of these appear to be worn or lose, immediate action should be taken. This will help you reduce risks to your forklift operator and help your team get their job done safely and efficiently.

The forklift operator should also check to make sure the forklift has a legible, accurate data plate that reflects the current configuration of the forklift, including any attachments being used. If the plate is missing or inaccurate, contact Professional Forklift Engineering Services, LLC at (843) 532-6469 or email at support@LiftTruckCapacityCalculator.com to get the data plate updated and the forklift re-certified.