Monthly Archives: April 2024

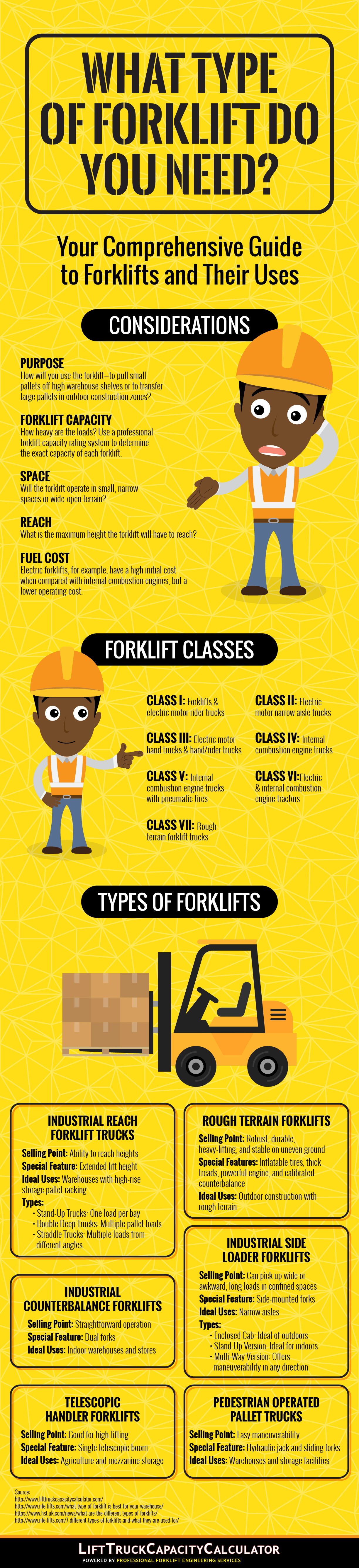

When you are in need of machinery to move products and other materials around your business or job site, using a forklift is one of the easiest and most efficient options. However, with the variety of forklifts available for the job, it can be difficult to decide which will be best for your situation. In order to solve this problem, it is important to consider a few factors.

Start by assessing the purpose of the forklift. Do you need it to pull pallets from a shelf or move large pallets around a construction site? What load capacity is needed to get the job done correctly and safely? Don’t forget to note the size of the space in which the forklift will operate. Choosing one too large will negate any benefits you hope to receive.

You also want to ensure that you have certified forklift operators who can easily operate the lift to help you cut down on time and expenses along the way. Research the type of forklifts available and assess your individual needs before buying or leasing for your company.

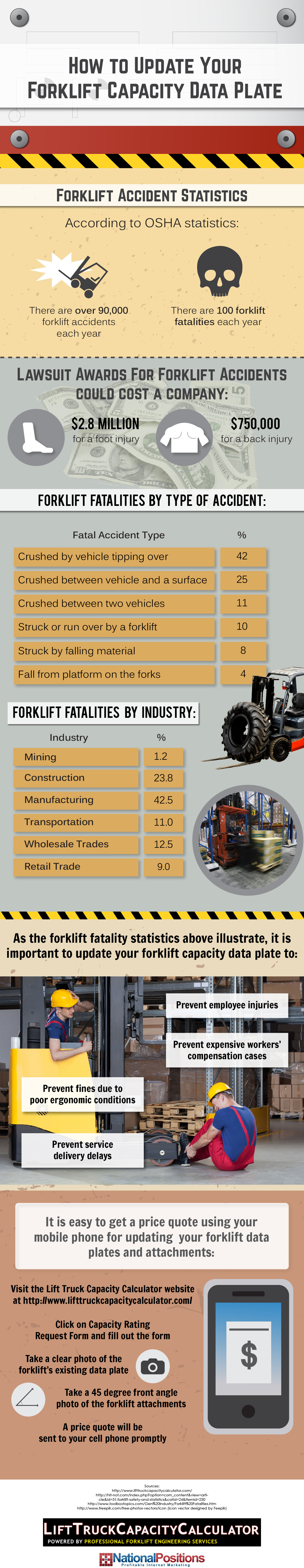

Forklift safety is not to be taken lightly. This equipment is involved in around 90,000 accidents every year and sometimes people sustain severely, and occasionally even fatal injuries from these incidents. Even if a forklift accident at the workplace doesn’t result in such serious consequences, it’s likely that a business will find still itself embroiled in workers’ compensation issues, and OSHA will always investigate the accident looking for regulatory violations. The infographic depicts the various recorded causes of accidents. Regardless of the ultimate resolution, a missing or incorrect data plate will be flagged, will result in OSHA fines, and can be legal fodder.

An incorrect or missing data plate can preclude an operator and the management team from understanding the lifting limitations of the machine. Properly trained forklift operators understand how to read the data plate and look for the forklift’s maximum capacity in a particular situation. Fortunately, there is now no reason to operate with an incorrect data plate because the specialists at Professional Forklift Engineering Services make it easy, quick, and cost effective to stay OSHA compliant. If we can help your business obtain the data plates and certifications you need please contact us for a quote.

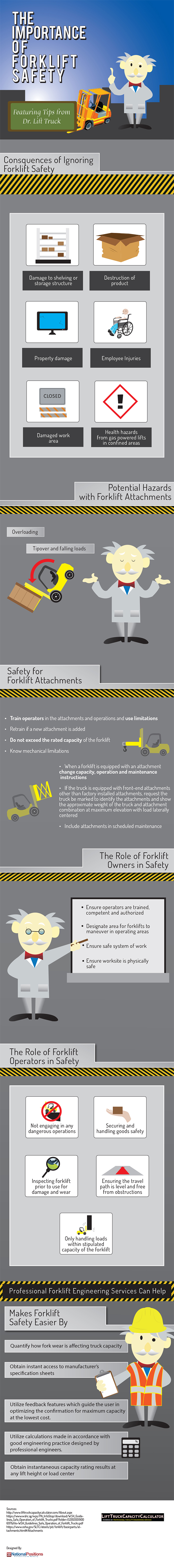

When working in a warehouse, or for any business that owns and operates forklifts, taking proper safety precautions is of the utmost importance. Owners of forklifts need to ensure that operators are fully trained and authorized to work with the equipment in order to meet compliance standards. Additionally, work areas should be cleared of debris and clutter, to allow forklifts to move and operate freely. This helps reduce the number of injuries and keeps employers and employees aware of best practices for operation at all times.

If forklift safety plans are ignored, there are a number of potential consequences, including:

Damage to warehouse shelving or storage structure

Destruction of product

Property damage

Employee injuries

Damaged work area as a result of spills or broken shelving

Health hazards

In addition, overloading a forklift could cause it to tip over. Damaged products and equipment will end up costing your business more in repair and replacement costs, which can be avoided by taking the time to do the job the right way.

Forklift attachments should be inspected regularly so that repairs to broken forks and other equipment can be made immediately. Train all operators on your attachments and, when you add a new attachment, be sure to retrain all personnel. Know the mechanical limitations of each forklift, and change the capacity, operation, and maintenance instructions when a forklift is equipped with an attachment.

Forklift operators should remain safe when driving a forklift, and they should secure all products before transporting. Inspect the forklift before each use, and always ensure the travel path is free of obstructions before beginning a job.