Monthly Archives: November 2025

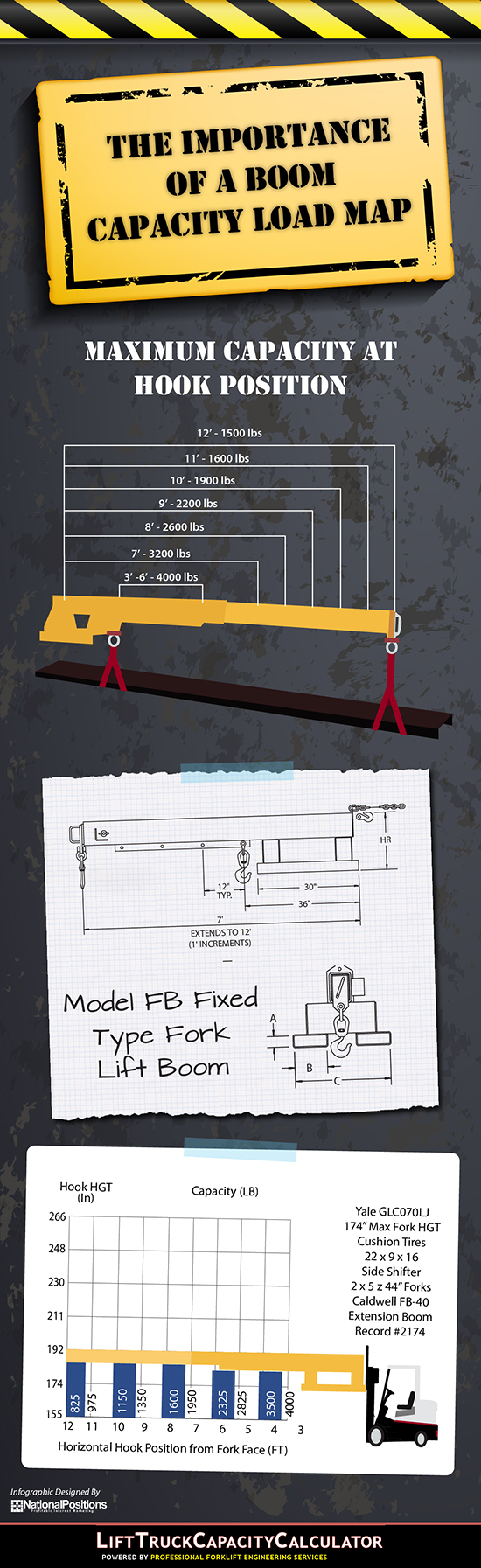

Understanding the capabilities and limitations of your machinery before use allows your employees to safely complete tasks. In addition, your business will see a decreased risk of injury, leading to greater productivity and efficiency. A boom capacity load map helps you achieve these goals, by giving your employees the information they need so they can safely lift materials in the warehouse or out on a job site.

Affixed to the forklift, the boom capacity load map shows the safe amount of weight that can be lifted at certain hook position intervals. The size of the load will affect the hook position, and you want to be sure to never lift over the capacity so that the highest levels of safety can be maintained at all times. Continually educating and retraining employees on the various equipment they use will ensure proper usage, and save time and money lost from injuries and broken machines.

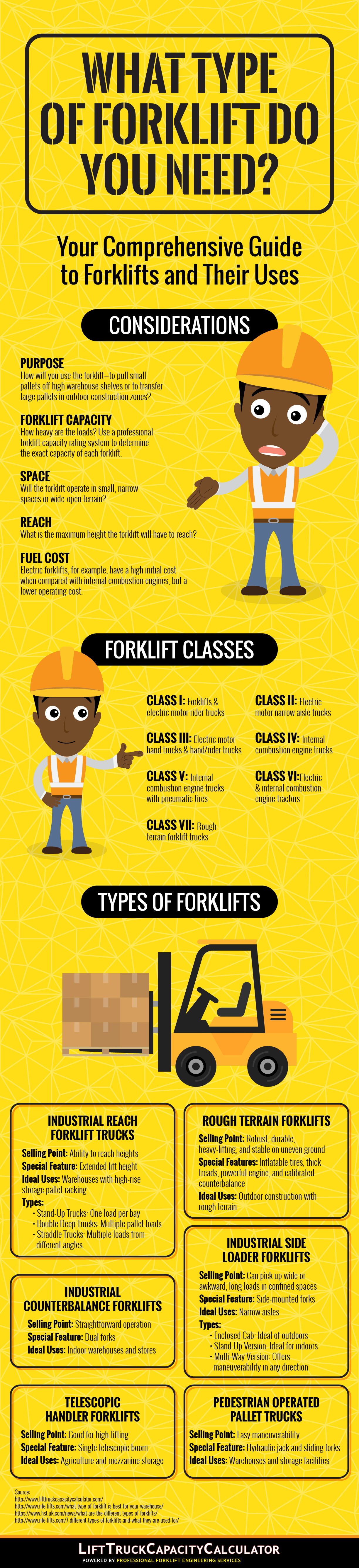

When you are in need of machinery to move products and other materials around your business or job site, using a forklift is one of the easiest and most efficient options. However, with the variety of forklifts available for the job, it can be difficult to decide which will be best for your situation. In order to solve this problem, it is important to consider a few factors.

Start by assessing the purpose of the forklift. Do you need it to pull pallets from a shelf or move large pallets around a construction site? What load capacity is needed to get the job done correctly and safely? Don’t forget to note the size of the space in which the forklift will operate. Choosing one too large will negate any benefits you hope to receive.

You also want to ensure that you have certified forklift operators who can easily operate the lift to help you cut down on time and expenses along the way. Research the type of forklifts available and assess your individual needs before buying or leasing for your company.

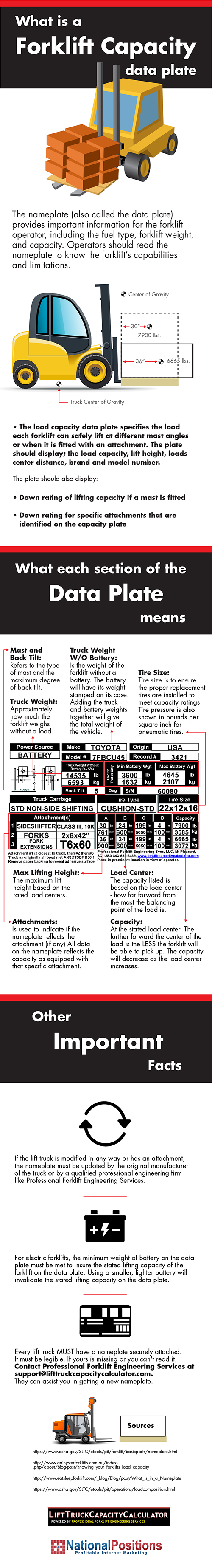

The data plate on a forklift is broken down into different sections, which each stand for a different characteristic and measurement. Some of these include:

Mast and Back Tilt Refers to the type of mast and the maximum degree of back tilt allowable.

Tire Size Ensures proper replacement tires are used to maintain levels of safety.

Load Center Gives a capacity based on how far forward from the mast the balancing point of the load is.

If any modifications are made to a forklift, or if it has an attachment, the forklift capacity plate must be updated to reflect the new capacity. Similarly, if a data plate goes missing or is illegible, you are required to replace it. To do so, contact Professional Forklift Engineering Services at support@lifttruckcapacitycalculator.com.

The maximum weight data placard on forklifts should never be regarded as the maximum amount able to be lifted. There are several factors that affect the lifting capacity, which is often reduced for various reasons. It is important to remember the lifting capacity is based upon the load center.

Did you know you lose weight-lifting capacity for every one inch beyond the actual load center? It is your responsibility to calculate the load center for any type of attachment used with the truck, including the original one. In addition, each time you switch attachments, it is essential to recalculate the load center and maximum load lift capacity of the forklift.

To learn more about the factors that affect the load center and load capacities, please feel free to continue reading the following infographic presented by Lift Truck Capacity Calculator. We can also provide assistance with determining the load center for a variety of attachments, as well as those that are worn by contacting us directly.