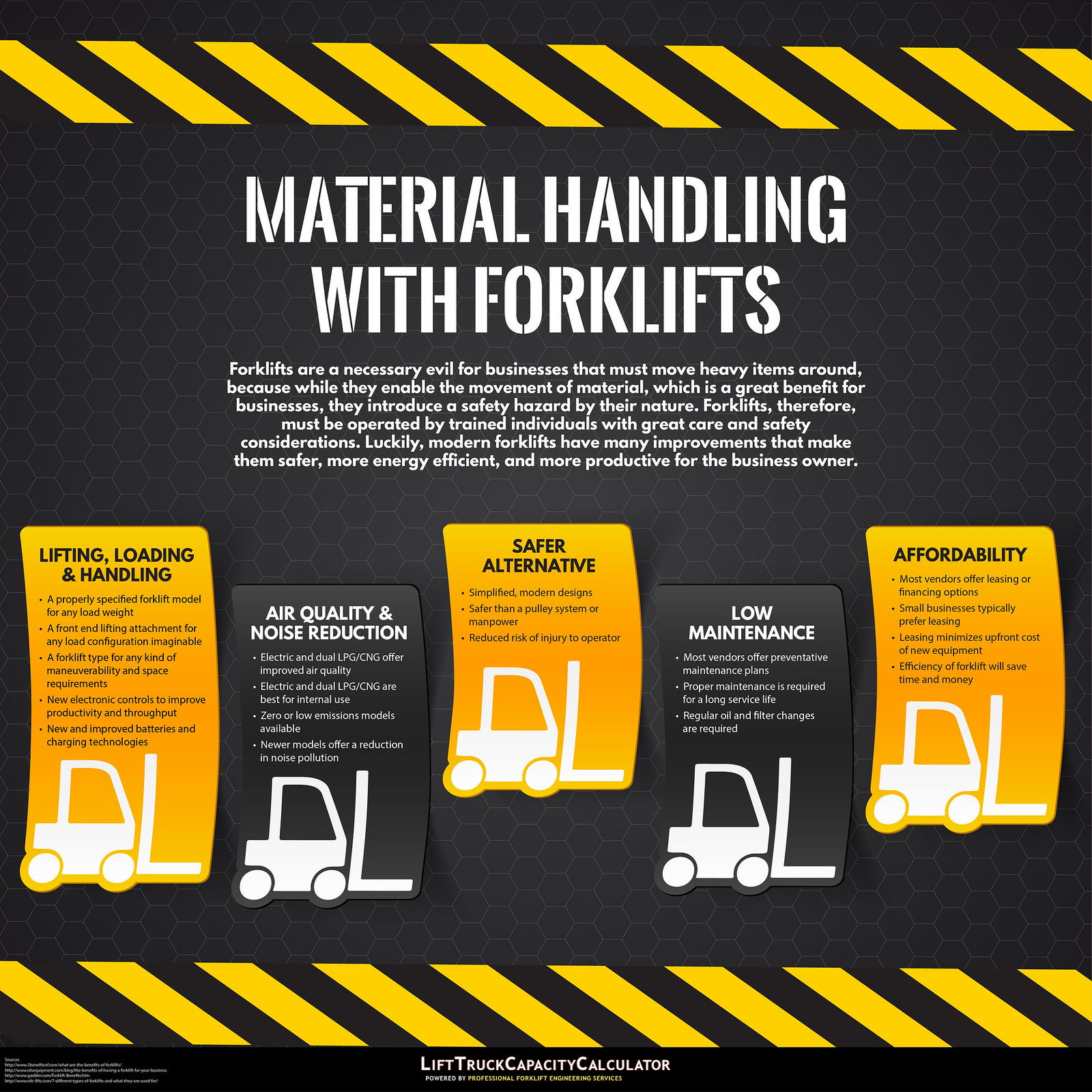

Moving materials and items around a business, warehouse, or job site is necessary for work to be done in many businesses. This means that companies rely on forklifts to move materials, but since safety is always concern and a priority for businesses, they must practice safety to minimize risk to employees and materials. Over time forklifts have become progressively more advanced and safer for operators, but lifting, lowering and moving heavy material with forklifts is precarious by nature, and thus requires skill, care, training and knowledge to be executed safely and efficiently.

First and foremost, the operator should always be aware of the load weight limits specified on the forklift data plate or data label for the particular forklift. Different types of lift trucks have different parameters for maneuverability, operation and safety, and the operator should aware, trained and comfortable with the operation the particular forklift machine. New forklift designs simplify the learning process for operators and deliver greater benefits for companies. For growing businesses, many different machine acquisition options are available to fit the business owners needs. Forklift acquisition should always be done through local dealers and sellers who can review the onsite requirements of the business owner, and provide the necessary local service and support required to keep the forklifts in good operating condition.