Monthly Archives: June 2025

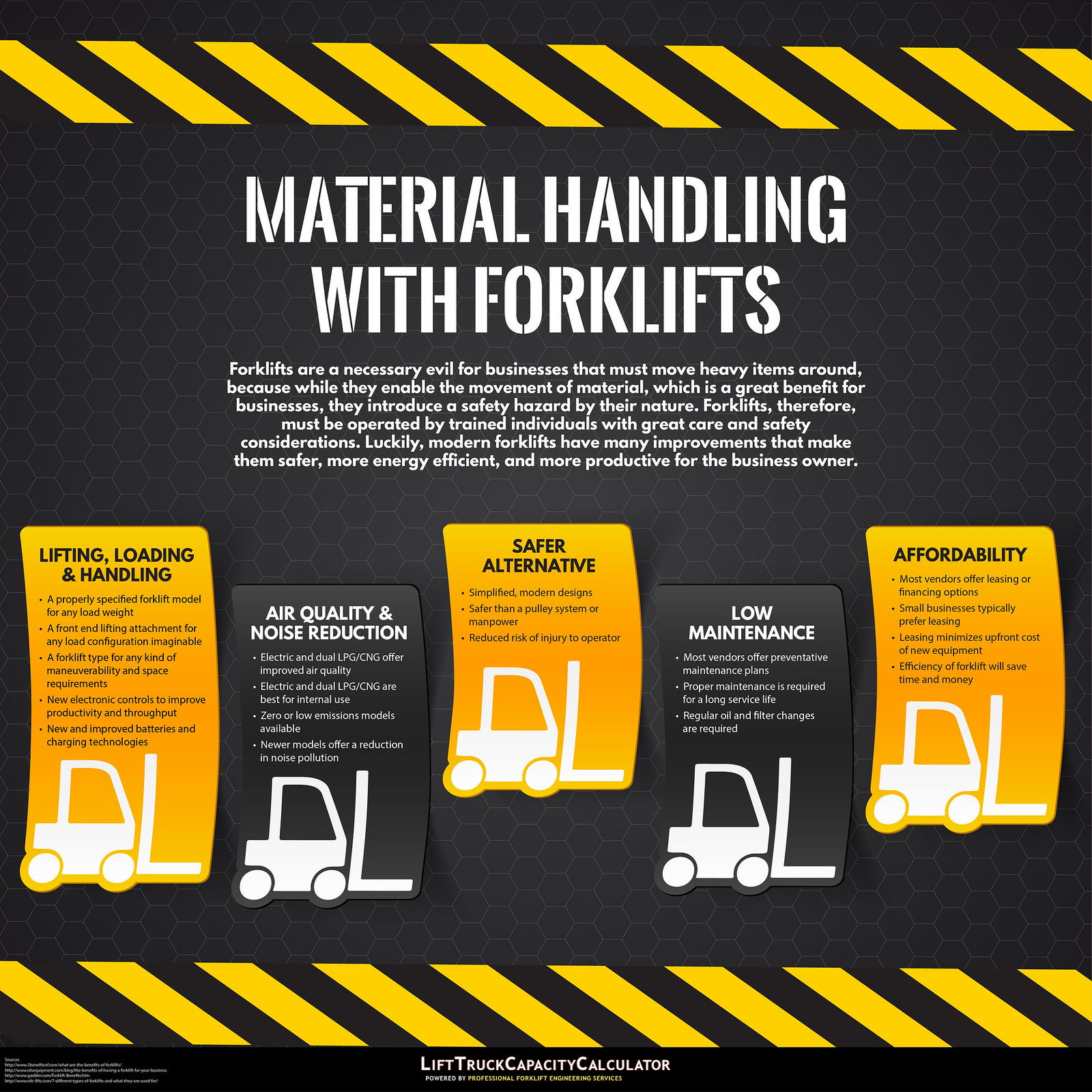

Moving materials and items around a business, warehouse, or job site is necessary for work to be done in many businesses. This means that companies rely on forklifts to move materials, but since safety is always concern and a priority for businesses, they must practice safety to minimize risk to employees and materials. Over time forklifts have become progressively more advanced and safer for operators, but lifting, lowering and moving heavy material with forklifts is precarious by nature, and thus requires skill, care, training and knowledge to be executed safely and efficiently.

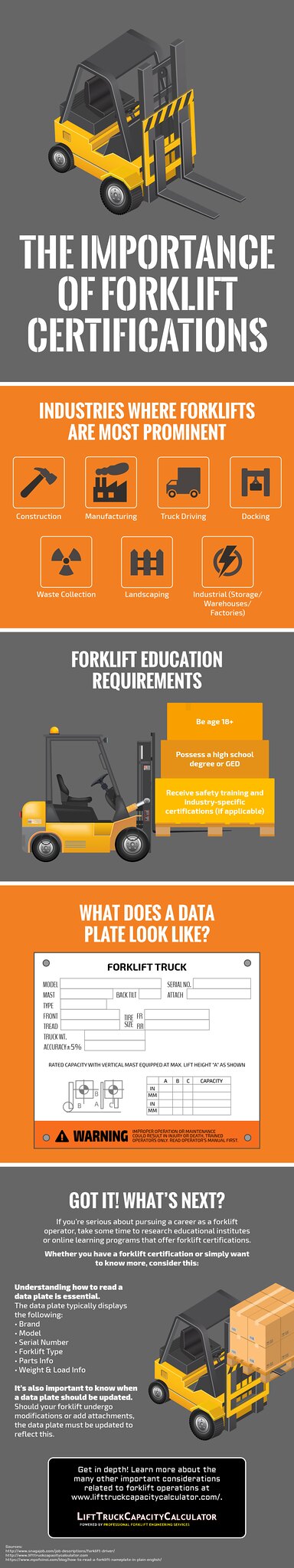

First and foremost, the operator should always be aware of the load weight limits specified on the forklift data plate or data label for the particular forklift. Different types of lift trucks have different parameters for maneuverability, operation and safety, and the operator should aware, trained and comfortable with the operation the particular forklift machine. New forklift designs simplify the learning process for operators and deliver greater benefits for companies. For growing businesses, many different machine acquisition options are available to fit the business owners needs. Forklift acquisition should always be done through local dealers and sellers who can review the onsite requirements of the business owner, and provide the necessary local service and support required to keep the forklifts in good operating condition.

As you grow your business, your need for material handling equipment will also grow. This may include forklifts and/or telehandlers as well as the types of attachments used on them to handle the material.

The forklift operator will learn how to read a forklift data plate or load chart which gives the operator information about the amount of load that can be safely lifted and to what heights and reaches. The operator will also learn to read the data plate and determine if the plate accurately represents the current configuration of the machine with the present attachments installed. If the data plate does not reflect the current attachments installed, the operator or company management may contact Professional Forklift Engineering Services, LLC at support@LiftTruckCapacityCalculator.com or 843-532-6469 to have the forklift data plate or load chart updated and the machine certified to the new safe lifting capacity.

When selecting a forklift for your business, it is important to take into account several different factors. There is no “one-size-fits-all” type of solution, even within the same industry or market segment.

Rather, each forklift should be customized to fit your specific needs and requirements. You want to evaluate and consider each of the following factors:

- The environment where the forklift will be used. Do you plan on using it indoors or outdoors or both?

- The type of facility where the forklift will be operated. Will you use it in a warehouse, in a shipping dock, or in some other type of commercial facility?

- The aisle width and door overhead clearance. The lift truck must be able to navigate and turn in the aisles and pass under any doors or overhead obstructions.

- The surfaces upon which the lift truck will operate. Will the machine be operated on smooth level polished concrete, irregular or smooth paved surfaces, gravel or rough terrain?

- The number of hours per day or week the machine will be used.

- The type of fuel used by the forklift. There are electric, gas, and diesel models to choose from and the fuel type should match the environment where it will be used.

- The maximum lifting height you require. You want to make sure the forklift can safely reach the heights you require.

- The maximum load capacity of items the forklift will be hauling. You want to choose a forklift that exceeds this amount to allow for load discrepancies from normal wear and tear.

- The type and dimensions of the loads. Some loads may require longer forks, fork extensions or a special lifting attachment.

- New or used machine? You can find both new and used models for sale but be sure to check the accuracy of the manufacturers data plate on used machines which may need to be updated per OSHA requirements prior to use.

For additional information on selecting the right forklift for any operation, we invite you to continue reviewing the following infographic. Remember to check out the tools, resources, and services available at Lift Truck Capacity Calculator to help with your research and contact professional Forklift Engineering Services, LLC with questions.

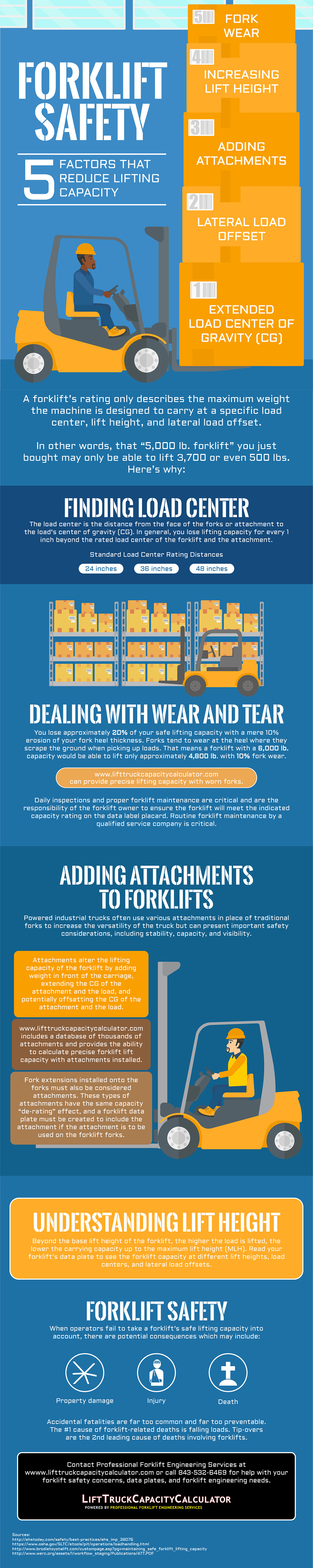

The maximum weight data placard on forklifts should never be regarded as the maximum amount able to be lifted. There are several factors that affect the lifting capacity, which is often reduced for various reasons. It is important to remember the lifting capacity is based upon the load center.

Did you know you lose the weight-lifting capacity for every one inch beyond the actual load center? It is your responsibility to calculate the load center for any type of attachment used with the truck, including the original one. In addition, each time you switch attachments, it is essential to recalculate the load center and maximum load lift capacity of the forklift.

To learn more about the factors that affect the load center and load capacities, please feel free to continue reading the following infographic presented by Lift Truck Capacity Calculator. We can also provide assistance with determining the load center for a variety of attachments, as well as those that are worn by contacting us directly.