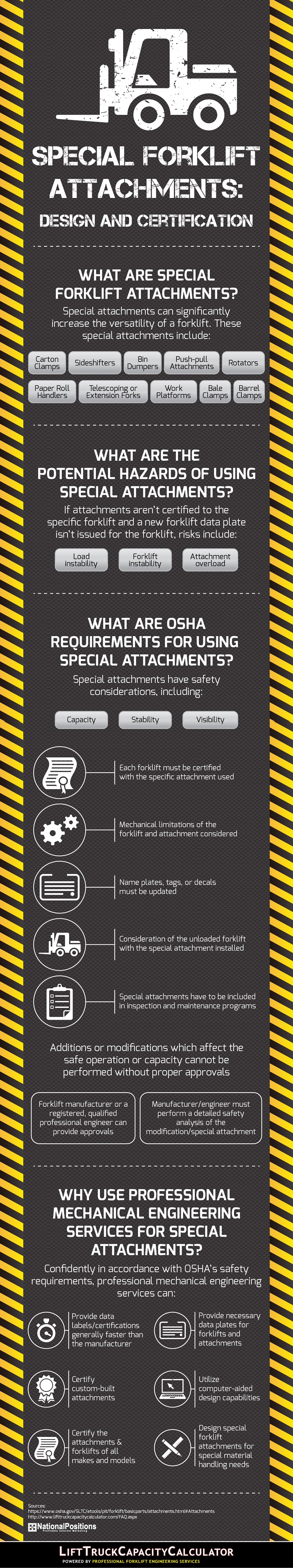

If your company uses a forklift, you know how important this piece of equipment is to your business and how versatile it can be with the use of special forklift attachments. These special attachments are used to transform from simple lifting forks, into a multi-purpose machine designated for a very particular task.

The different types of special forklift attachments are virtually unlimited but typical attachments include side shifters, fork positioners, rotators, paper roll clamps, box clamps, bale clamps, appliance clamps, concrete block clamps, push-pulls (also called slip-sheet attachments), load extenders and stabilizers, hay clamps, bale spears, carriages, skips or waste bins, scoops, buckets, booms, crane jibs, fork mounted hooks, forks, fork extensions, bulk bag handlers, snow ploughs, yard scrapers, fork mounted drum handlers and drum rotators, work platforms and cages just to name a few. Special custom made and in-house fabricated attachments are also often used.

If you need to use special forklift attachments, you will also need to certify and label the forklift with an updated data plate to reflect the new forklift configuration and the new lifting capacity. Updating the data plate when you change front end attachments is an OSHA regulation that falls under OSHA regulation CFR 29 1910.178 referencing “powered industrial truck addition/modification approval and marking requirements”. Professional Forklift Engineering Services has qualified professional engineers that can help you get your forklifts OSHA compliant in this regard.